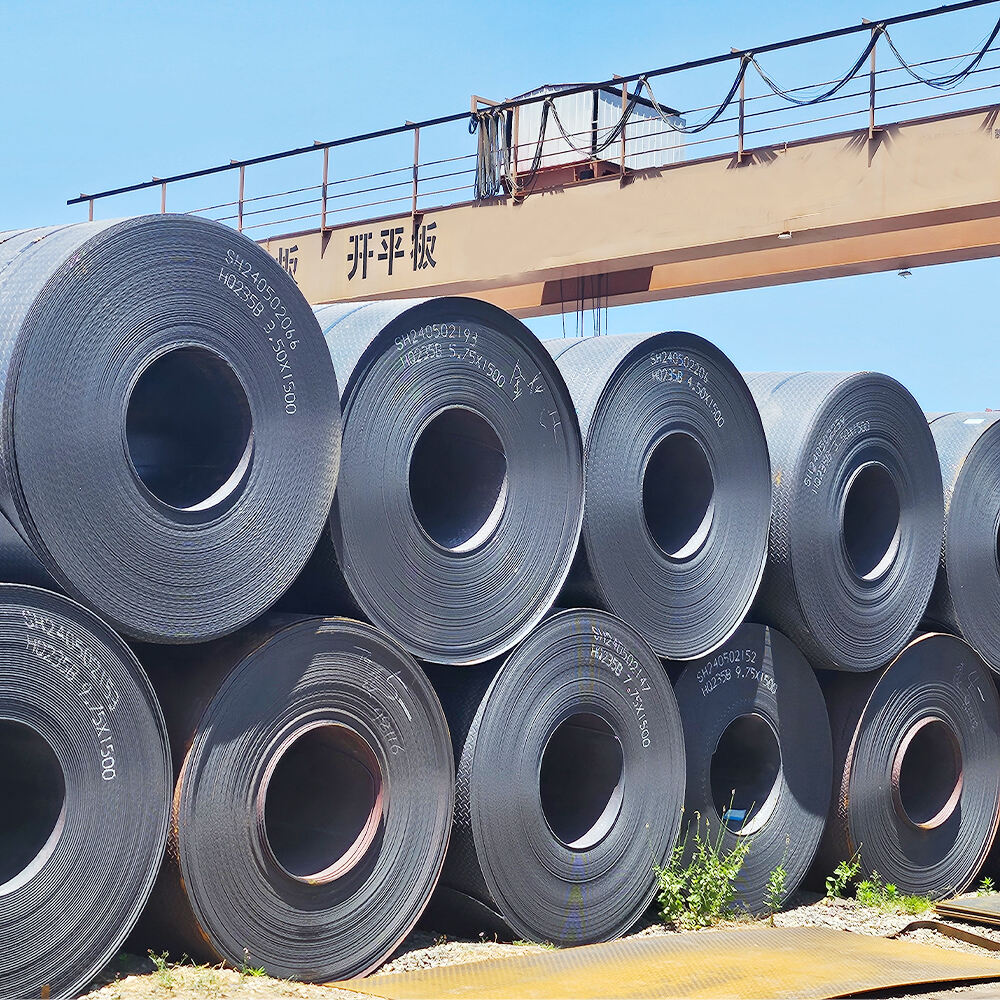

carbon steel coil

Carbon steel coil represents a fundamental material in modern manufacturing, combining strength, versatility, and cost-effectiveness. This engineered product consists of iron alloyed primarily with carbon, typically containing between 0.12% and 2% carbon content, which significantly influences its mechanical properties. The manufacturing process involves hot rolling or cold rolling techniques, resulting in a continuous strip of steel formed into a coil for efficient storage and transportation. These coils are produced in various thicknesses, widths, and grades to meet diverse industrial requirements. The material exhibits excellent formability, weldability, and durability, making it ideal for numerous applications across construction, automotive, and manufacturing sectors. Carbon steel coils undergo rigorous quality control processes, including surface treatment and coating applications, to enhance their resistance to corrosion and environmental factors. The controlled manufacturing process ensures consistent material properties throughout the coil, facilitating reliable performance in end-use applications. Modern production techniques incorporate advanced technologies for precise thickness control, surface finish optimization, and dimensional accuracy, resulting in a product that meets stringent industry standards and specifications.

×

×