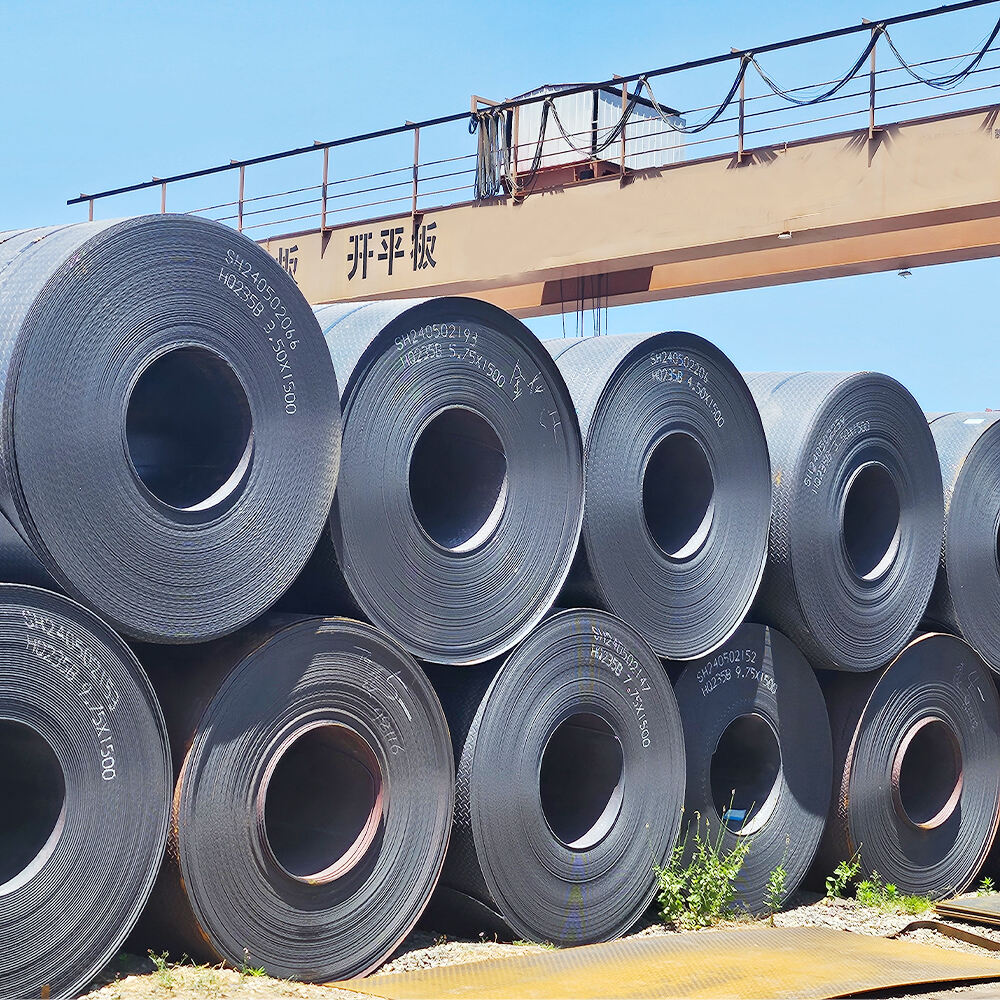

hot rolled carbon steel coil

Hot rolled carbon steel coil represents a fundamental product in the steel manufacturing industry, produced through a high-temperature rolling process that transforms steel slabs into versatile sheets. This manufacturing method involves heating the steel to temperatures exceeding 1700°F, allowing for precise manipulation of the material's physical properties. The process creates a steel product characterized by its consistent thickness, excellent formability, and reliable mechanical properties. These coils feature a distinctive mill scale surface finish and slightly rounded edges, making them ideal for applications requiring strength and durability. The material's chemical composition, primarily consisting of iron and carbon with trace amounts of other elements, contributes to its exceptional strength-to-weight ratio and cost-effectiveness. Hot rolled carbon steel coils are manufactured in various widths, thicknesses, and grades to meet diverse industrial requirements. The material's inherent properties make it particularly suitable for construction, automotive manufacturing, industrial equipment, and structural applications where precise dimensional tolerances are not critical. The production process ensures optimal grain structure and uniform mechanical properties throughout the coil, resulting in consistent performance across applications.

×

×