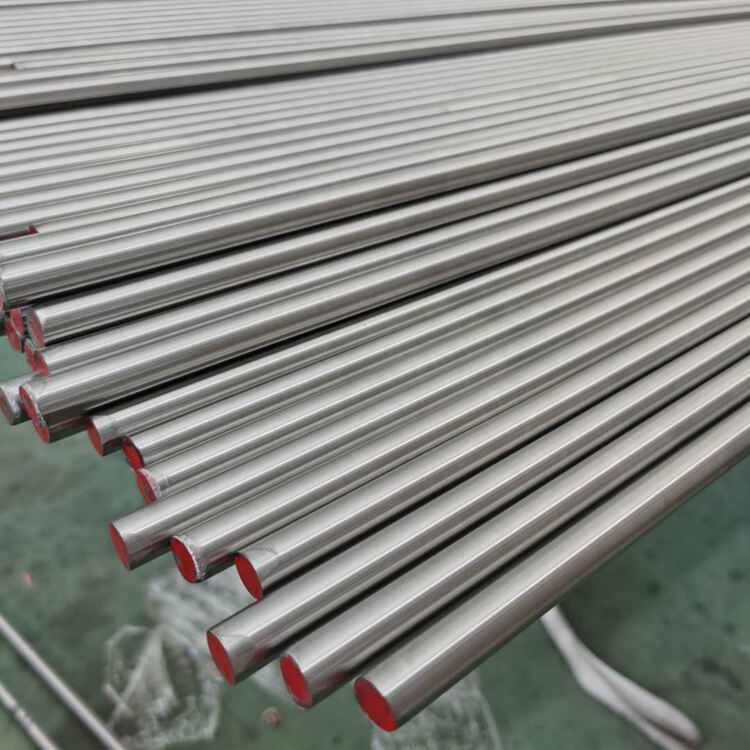

stainless steel 410 round bar

Stainless steel 410 round bar is a versatile martensitic stainless steel product that combines excellent mechanical properties with moderate corrosion resistance. This material features a minimum of 11.5% chromium content, making it suitable for various demanding applications. The round bar format offers exceptional machinability and can be heat treated to achieve desired hardness levels, typically ranging from 150 to 425 BHN. Its unique composition allows for superior wear resistance while maintaining good ductility and impact strength. The 410 grade stands out for its ability to be hardened through heat treatment, enabling customization of mechanical properties to meet specific application requirements. These round bars are manufactured through precision rolling processes, ensuring consistent diameter tolerances and surface finish quality. The material exhibits magnetic properties and maintains its structural integrity across a wide temperature range, from cryogenic to elevated temperatures up to 1200°F. In industrial applications, stainless steel 410 round bars serve as essential components in pump shafts, valve stems, fasteners, and various architectural applications where both strength and corrosion resistance are crucial.

×

×