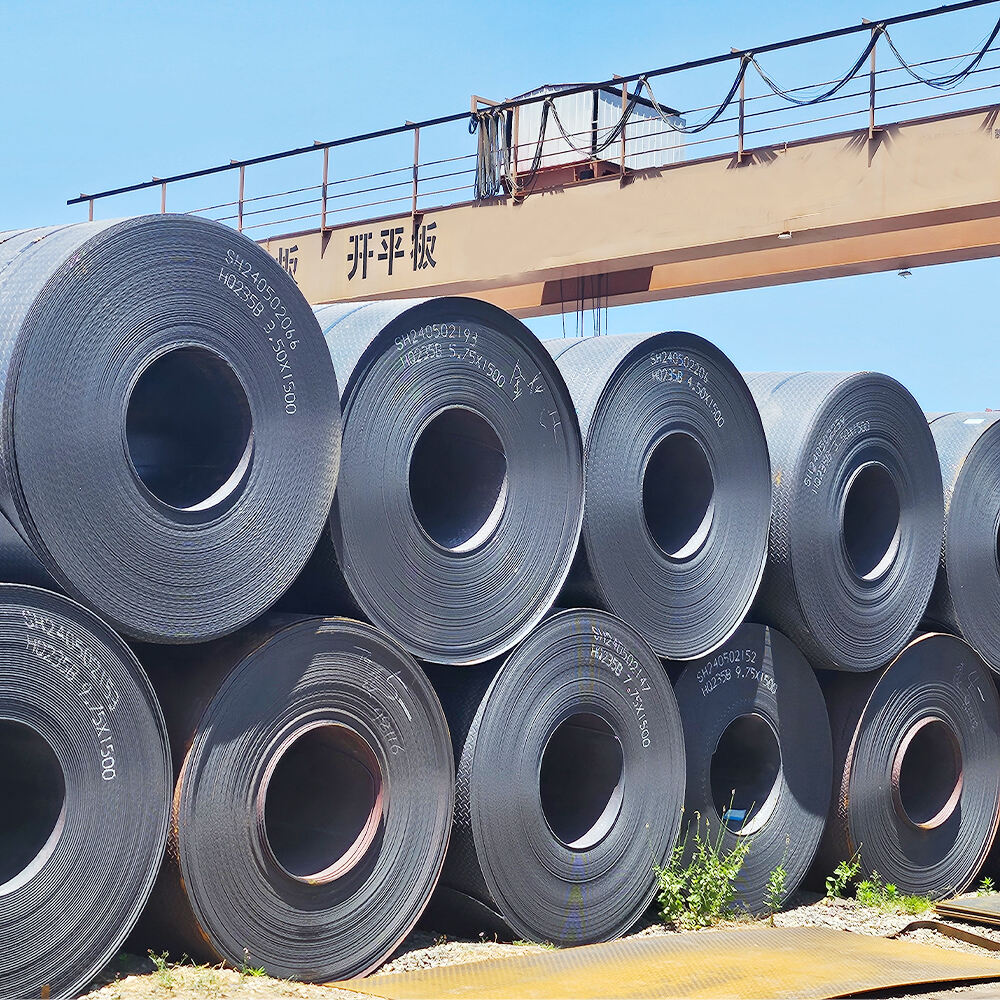

cold rolled carbon steel coil

Cold rolled carbon steel coil represents a refined form of steel manufacturing that delivers superior surface finish and precise dimensional accuracy. This specialized steel product undergoes a meticulous cold rolling process at room temperature, where hot rolled steel is compressed between rollers to achieve reduced thickness and enhanced mechanical properties. The process significantly improves the material's strength, hardness, and surface quality while maintaining tight thickness tolerances. These coils feature uniform thickness throughout their length, making them ideal for applications requiring consistent material properties. The manufacturing process ensures excellent flatness and superior surface finish, which is particularly valuable in applications where appearance matters. Cold rolled carbon steel coils exhibit remarkable formability and weldability, making them versatile for various industrial applications. They are widely used in automotive components, home appliances, construction materials, and precision engineering parts. The material's inherent characteristics include high tensile strength, good ductility, and exceptional wear resistance, making it a preferred choice for manufacturers across different sectors. The controlled processing environment ensures minimal internal stresses and optimal grain structure, contributing to the material's overall performance and reliability.

×

×