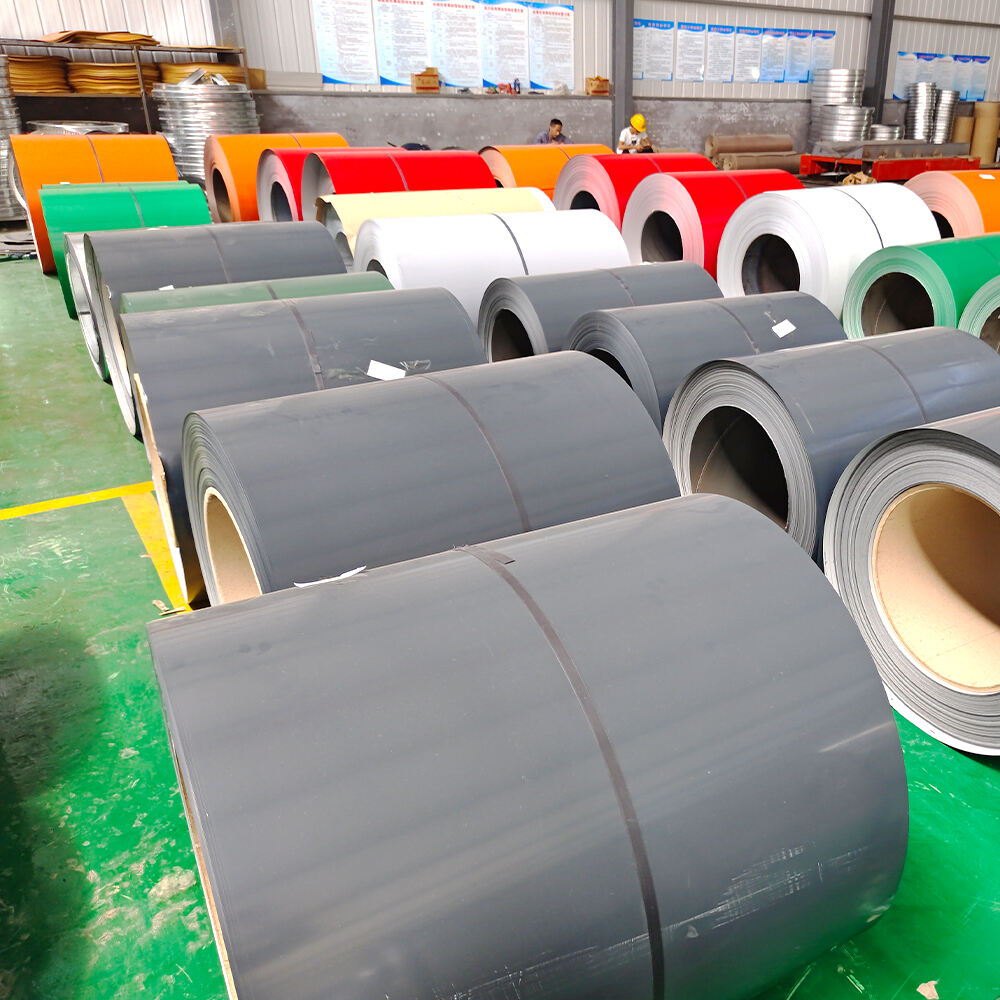

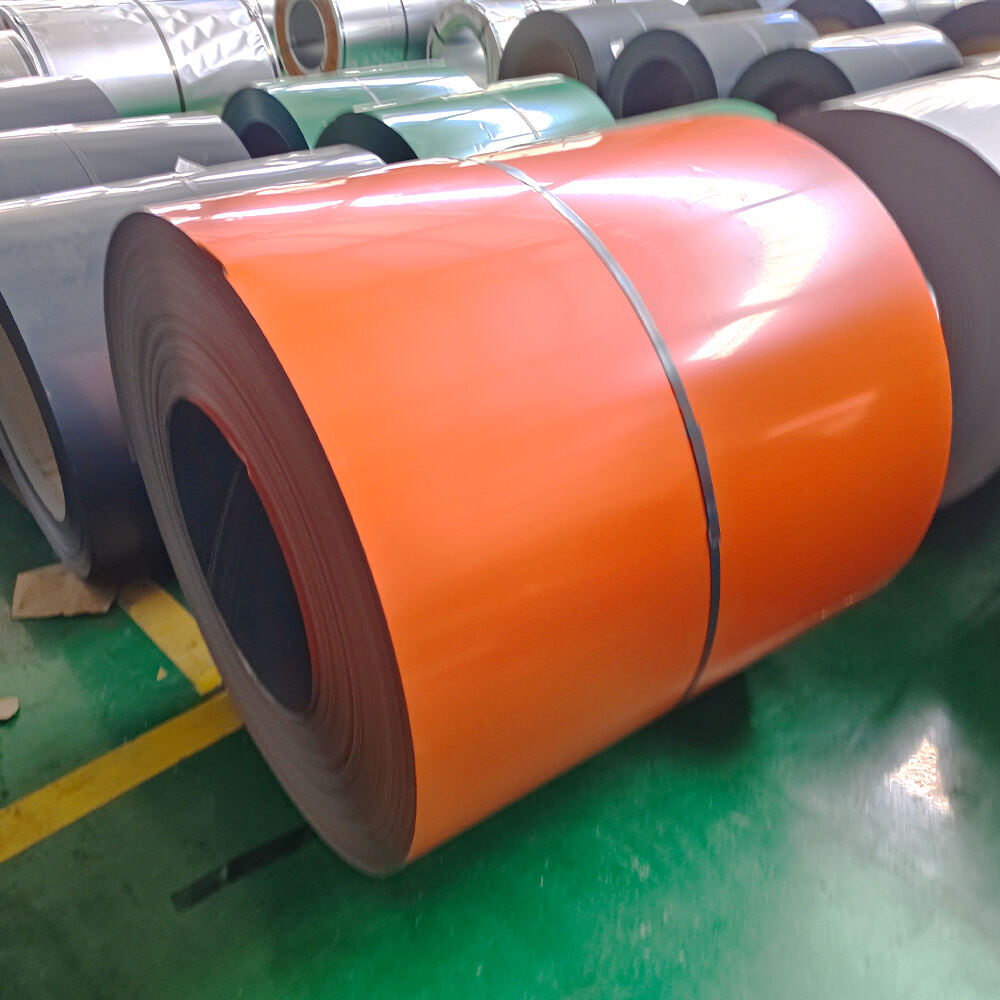

ppgi and ppgl

PPGI (Pre-painted Galvanized Iron) and PPGL (Pre-painted Galvalume Steel) represent advanced coated steel products that combine durability with aesthetic appeal. These materials consist of a steel substrate treated with a protective metallic coating, followed by a primer and a finishing paint layer. The base steel undergoes hot-dip galvanization or galvalume coating processes, creating a resilient barrier against corrosion. The pre-painting process involves applying a chemical treatment, primer, and color coating under strictly controlled conditions. PPGI utilizes zinc coating for corrosion resistance, while PPGL employs an aluminum-zinc alloy coating that offers enhanced durability. These materials find extensive applications in construction, particularly in roofing, wall cladding, and architectural panels. Their versatility extends to manufacturing sectors, including appliances, HVAC systems, and automotive components. The manufacturing process ensures uniform coating thickness and superior adhesion, resulting in products that maintain their appearance and protective properties over extended periods. Both PPGI and PPGL offer customizable color options and surface finishes, making them ideal for projects requiring specific aesthetic requirements while maintaining structural integrity.

×

×