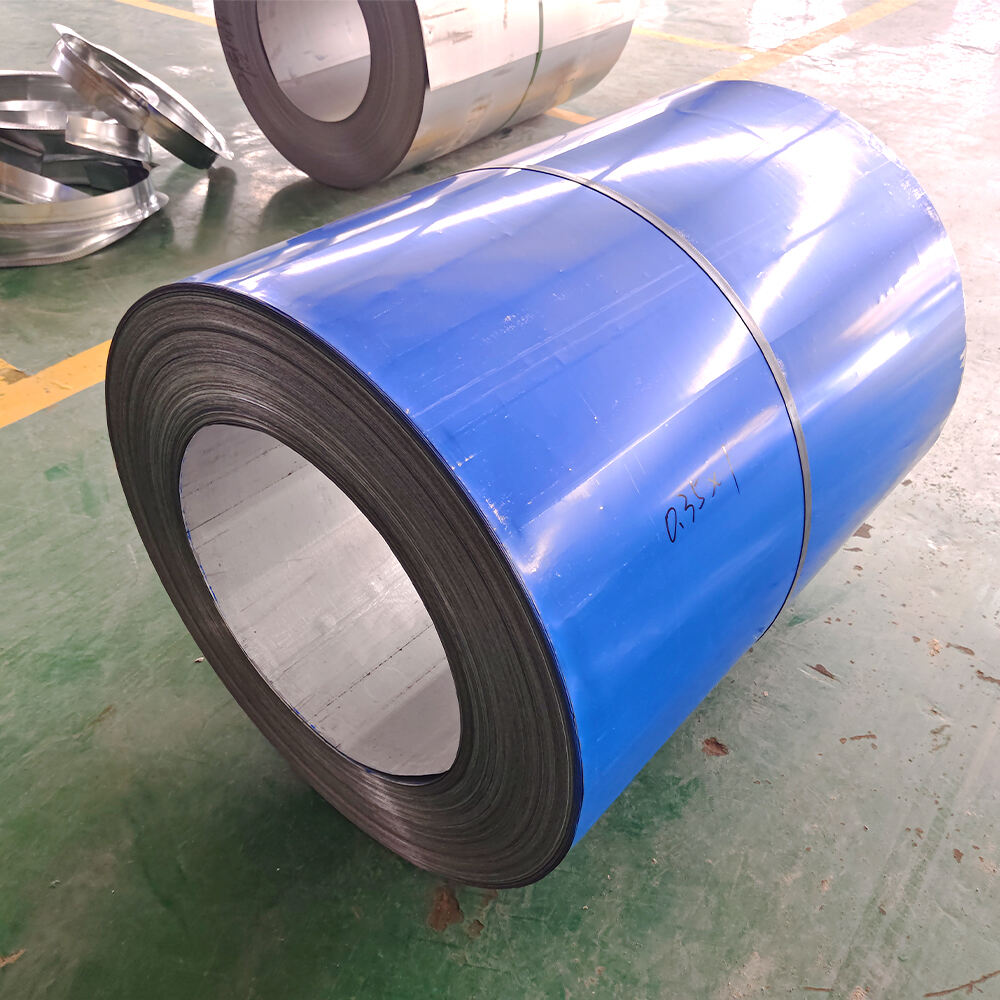

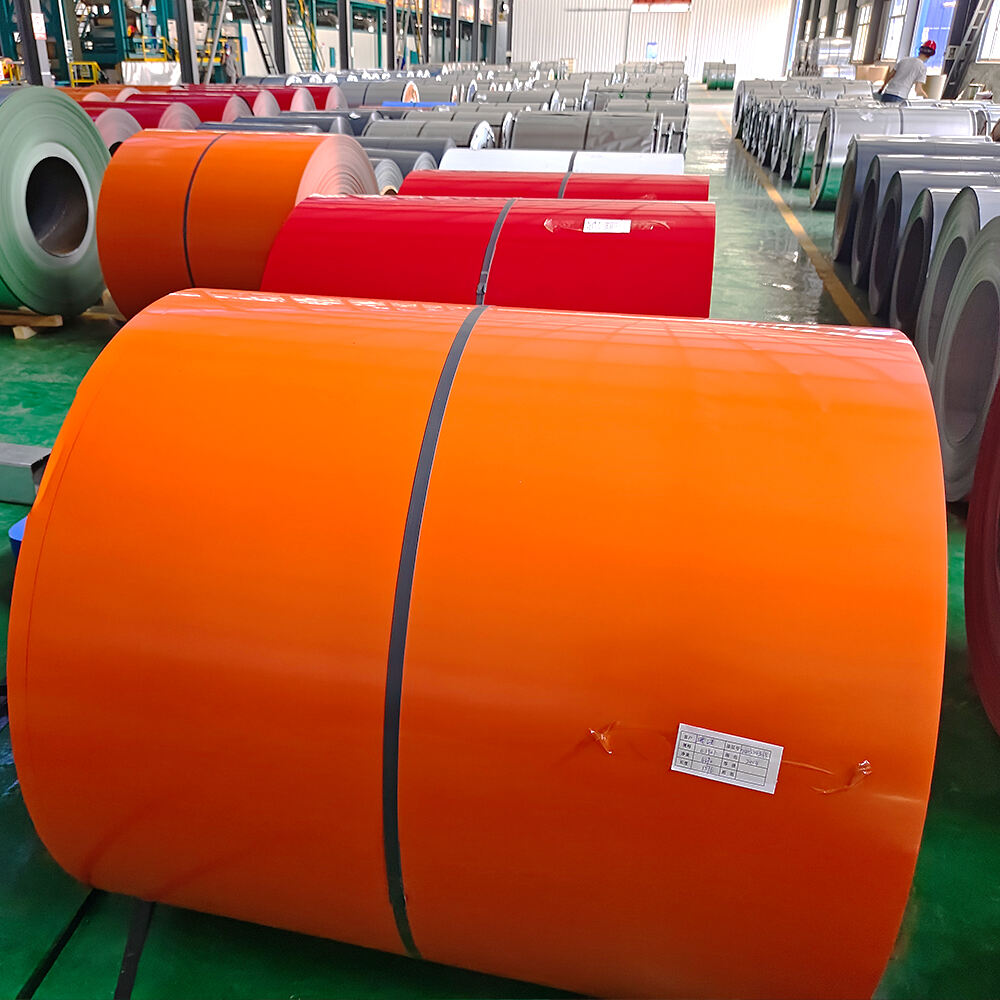

ppgi steel sheet

PPGI steel sheet, also known as pre-painted galvanized iron, represents a sophisticated evolution in construction materials, combining durability with aesthetic appeal. This versatile material consists of a steel core that undergoes hot-dip galvanization, followed by a specialized chemical treatment and multiple layers of primer and paint coatings. The manufacturing process ensures exceptional corrosion resistance while maintaining the structural integrity of steel. The sheet's composition typically includes a zinc coating weight of 60-275g/m2 and paint coating thickness ranging from 18-25 microns, depending on specific applications. PPGI steel sheets excel in both industrial and commercial applications, offering remarkable weather resistance and color stability. They are extensively used in roofing systems, wall cladding, industrial buildings, and various architectural applications. The material's design flexibility allows for different surface finishes, ranging from smooth to textured, and accommodates a wide spectrum of colors. Its technological features include advanced anti-corrosion properties, UV resistance, and excellent formability, making it suitable for complex structural designs. The sheets can be easily cut, bent, and formed without compromising the integrity of the protective coatings, ensuring long-term performance and reduced maintenance requirements.

×

×