ppgi company

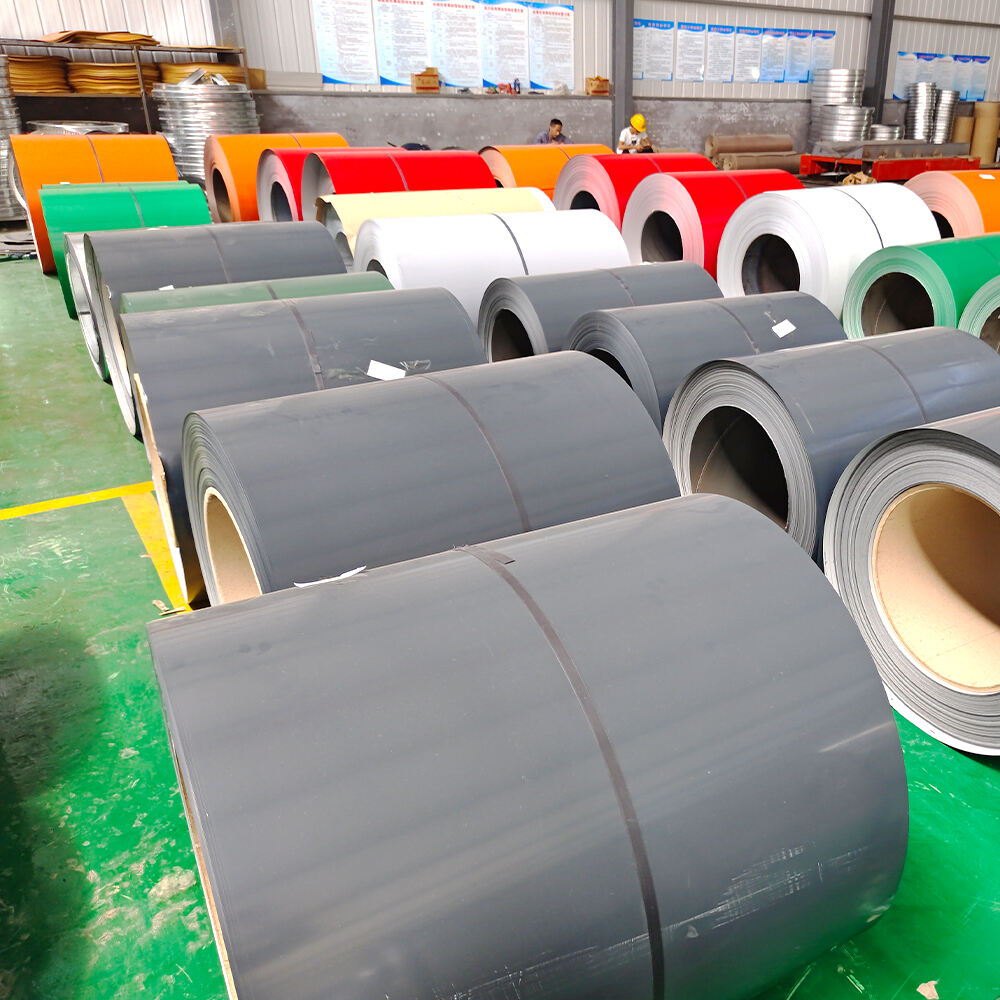

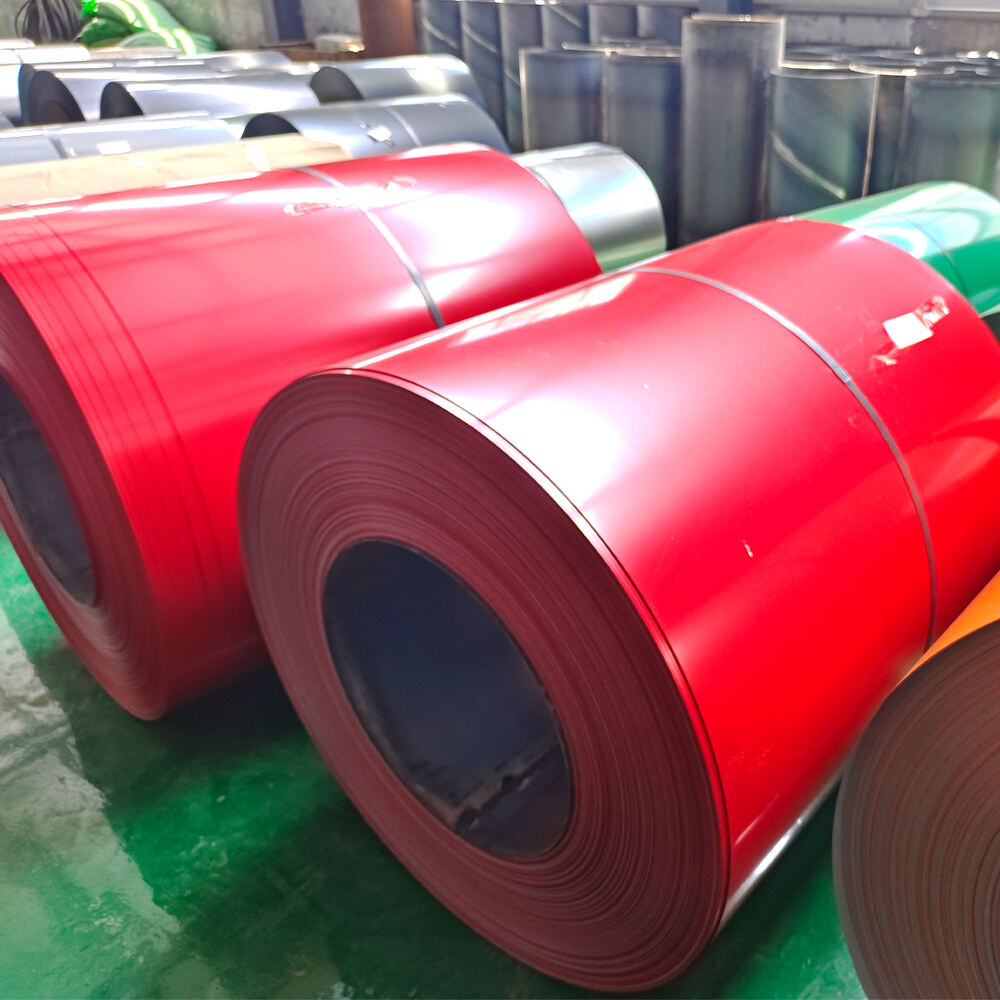

A PPGI (Pre-Painted Galvanized Iron) company stands at the forefront of modern construction materials manufacturing, specializing in the production of high-quality coated steel products. These companies employ advanced continuous coating technology to create steel sheets that combine superior corrosion resistance with aesthetic appeal. The manufacturing process involves hot-dip galvanizing followed by sophisticated paint application systems, ensuring uniform coating and excellent durability. PPGI companies typically maintain state-of-the-art production facilities equipped with automated quality control systems, precise coating thickness monitors, and environmental control measures. They serve various sectors including construction, automotive, appliance manufacturing, and industrial applications. The production line incorporates multiple stages from surface preparation to final inspection, utilizing cutting-edge chromate treatment and primer application technologies. Modern PPGI companies also emphasize sustainability, implementing eco-friendly coating processes and recycling systems. Their products undergo rigorous testing for weather resistance, color retention, and mechanical properties, ensuring compliance with international standards. These companies often provide customization options for coating thickness, color selection, and surface finish, meeting diverse customer requirements across global markets.

×

×