ppgl and ppgi

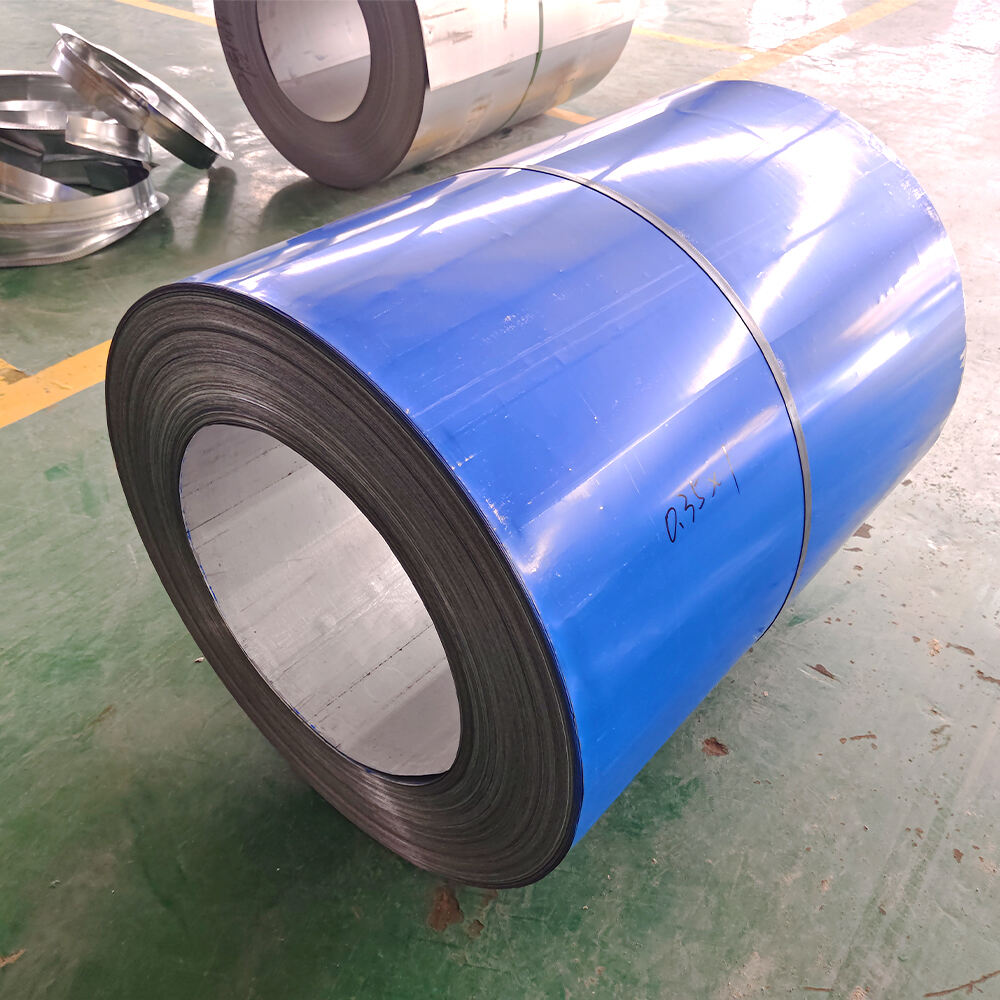

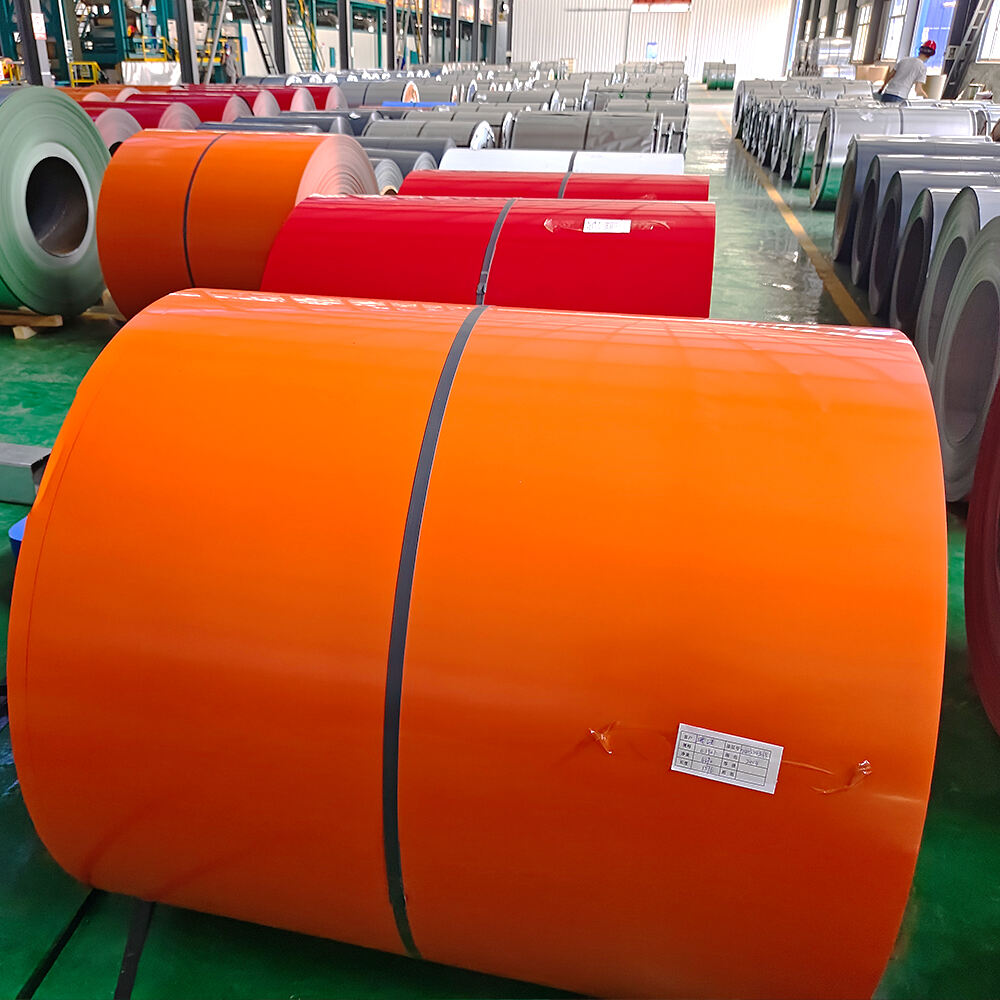

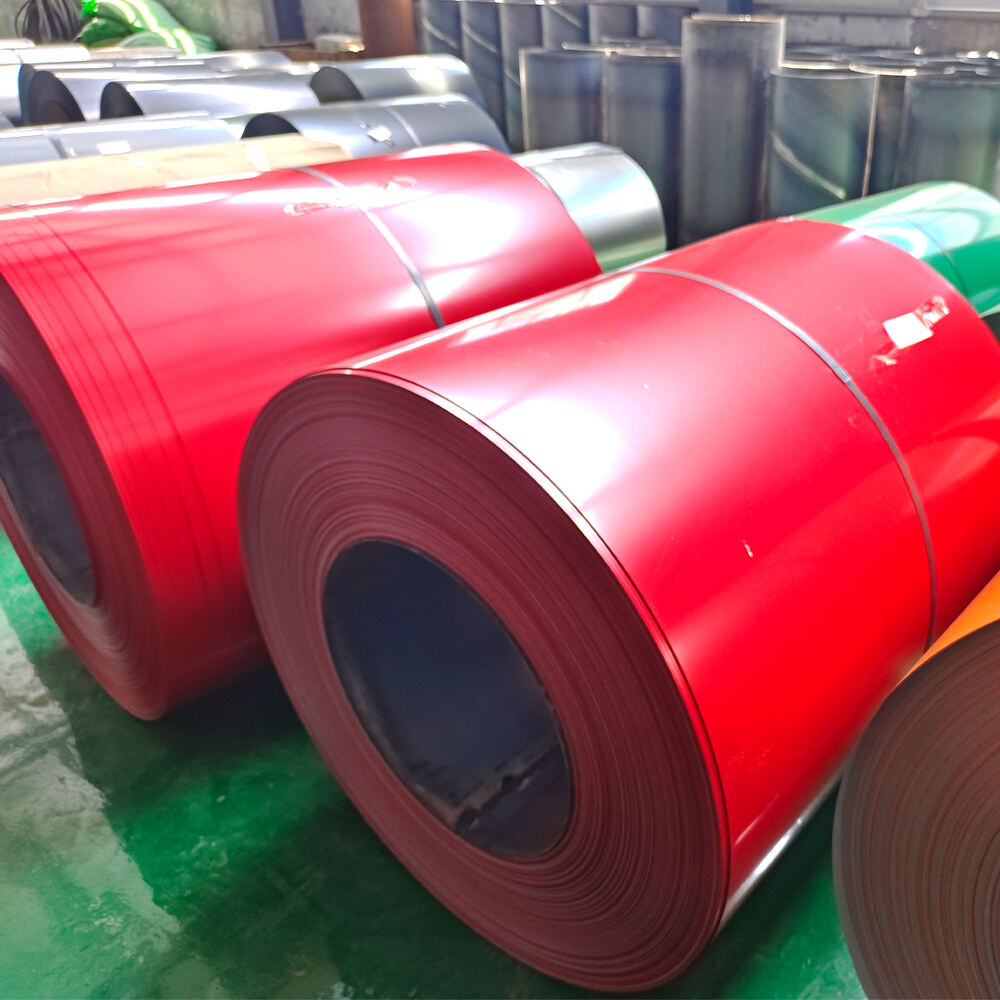

PPGL (Pre-painted Galvalume) and PPGI (Pre-painted Galvanized Iron) are advanced coated steel products that have revolutionized the construction and manufacturing industries. These materials consist of steel sheets coated with protective layers and finished with a paint system that enhances both their durability and aesthetic appeal. PPGL utilizes an aluminum-zinc alloy coating, while PPGI features a zinc coating, both offering superior corrosion resistance. The pre-painting process involves multiple layers, including a primer coat and a finish coat, which can be customized in various colors and textures. These materials exhibit exceptional weather resistance, thermal efficiency, and structural integrity, making them ideal for diverse applications. They are widely used in roofing systems, wall cladding, industrial buildings, agricultural facilities, and various architectural applications. The manufacturing process employs state-of-the-art technology to ensure consistent quality, precise coating thickness, and optimal adhesion between layers. Both PPGL and PPGI offer excellent formability, allowing them to be shaped and bent without compromising the integrity of the coating system.

×

×