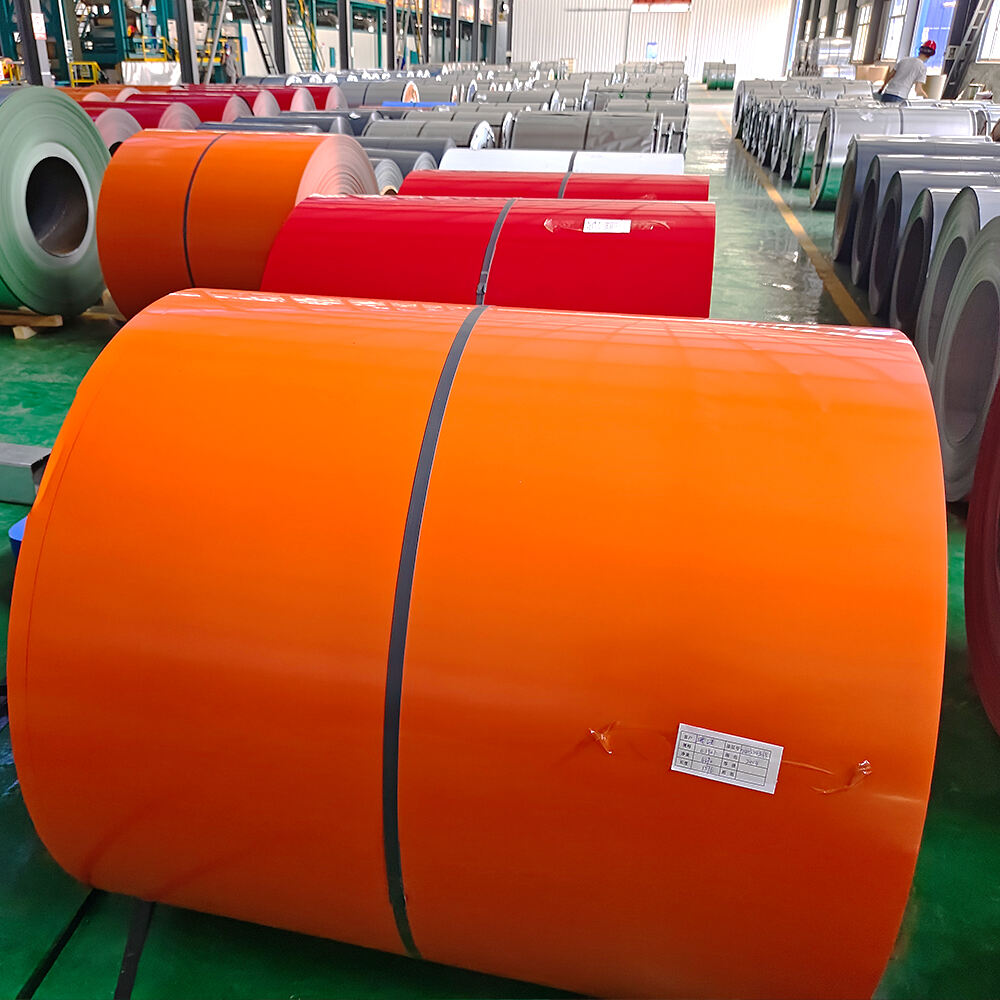

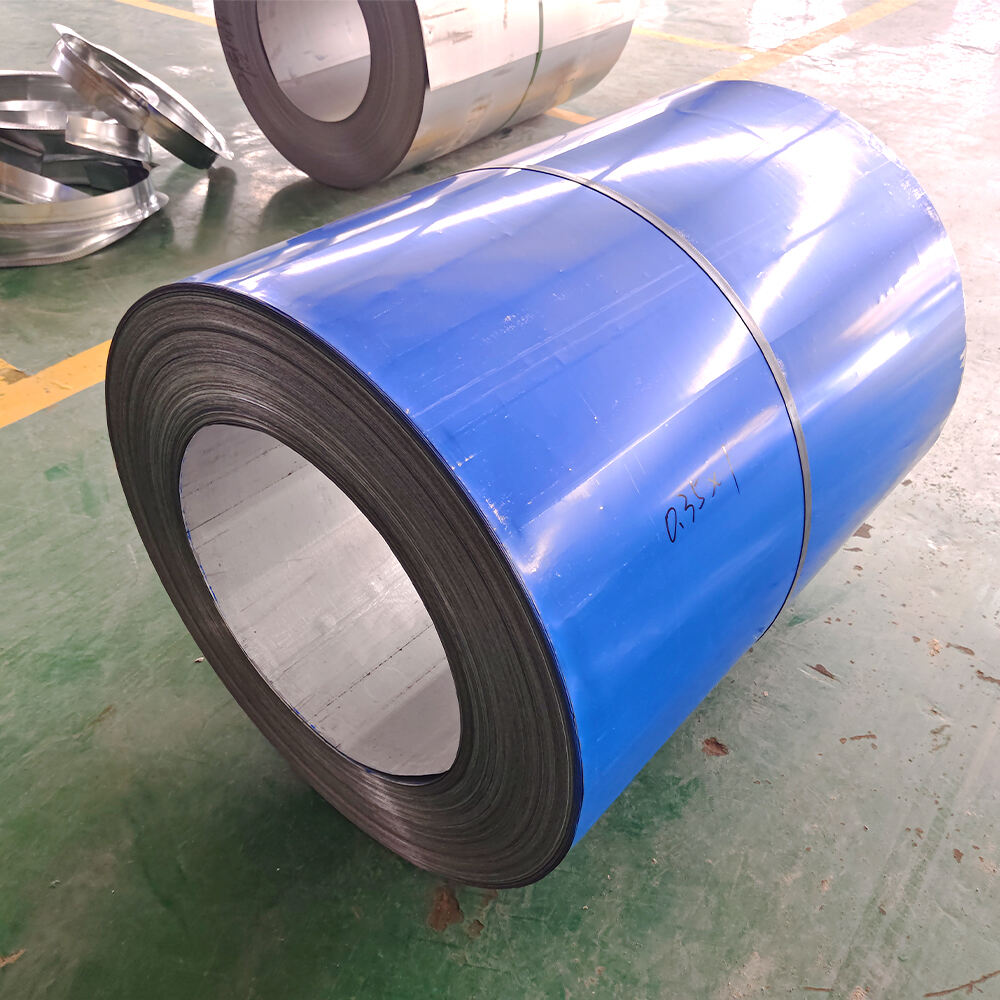

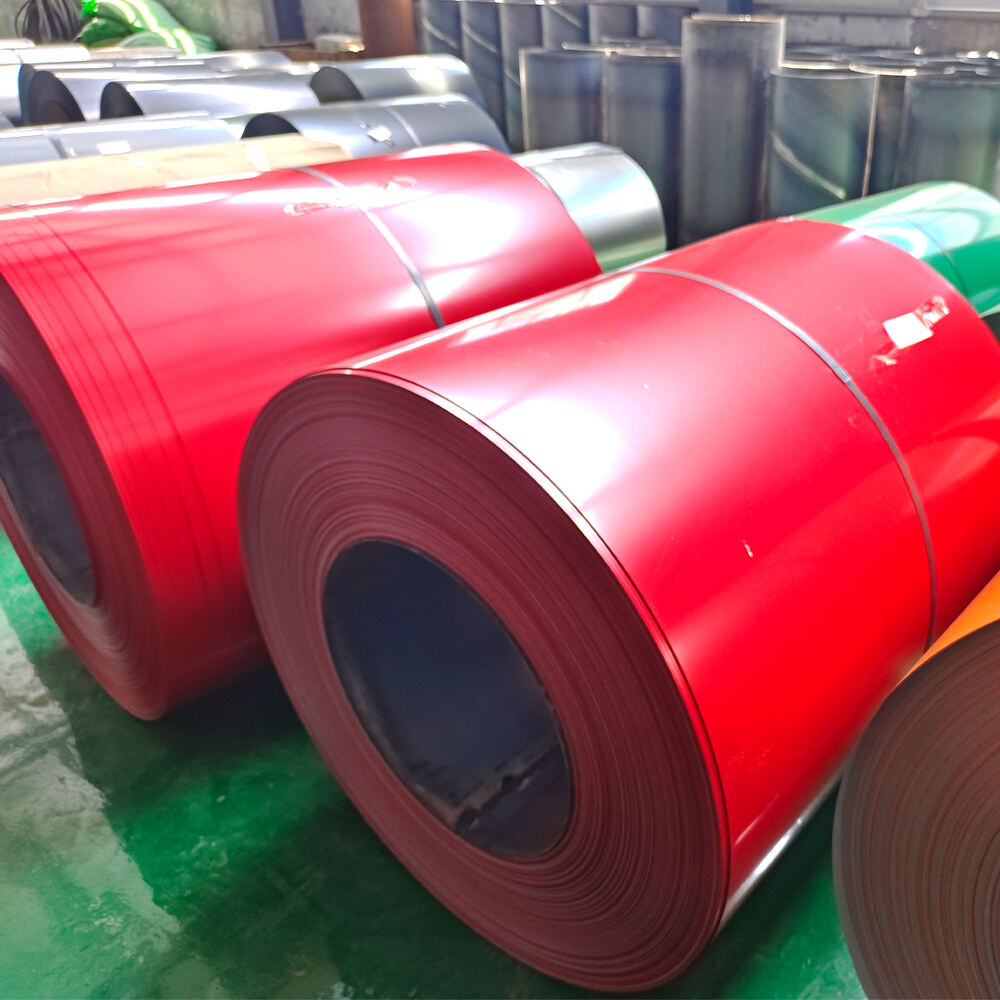

pre painted galvanized iron

Pre painted galvanized iron (PPGI) represents a revolutionary advancement in metal construction materials, combining durability with aesthetic appeal. This innovative product consists of a steel core that undergoes hot-dip galvanization, followed by a sophisticated pre-painting process that includes multiple protective layers. The base steel receives a zinc coating through galvanization, creating a robust barrier against corrosion. The surface then undergoes chemical treatment and primer application before the final color coating is applied. This multi-layer structure ensures superior protection against environmental factors while maintaining visual appeal. The material's versatility allows for various applications across construction, roofing, wall cladding, and industrial equipment manufacturing. Modern PPGI products feature advanced coating technologies that offer enhanced UV resistance, superior color retention, and improved scratch resistance. The manufacturing process ensures uniform coating thickness and consistent color appearance, making it ideal for large-scale architectural projects where aesthetic consistency is crucial. With customizable thickness options ranging from 0.12mm to 1.5mm and a wide spectrum of color choices, PPGI meets diverse project requirements while maintaining its core protective properties.

×

×