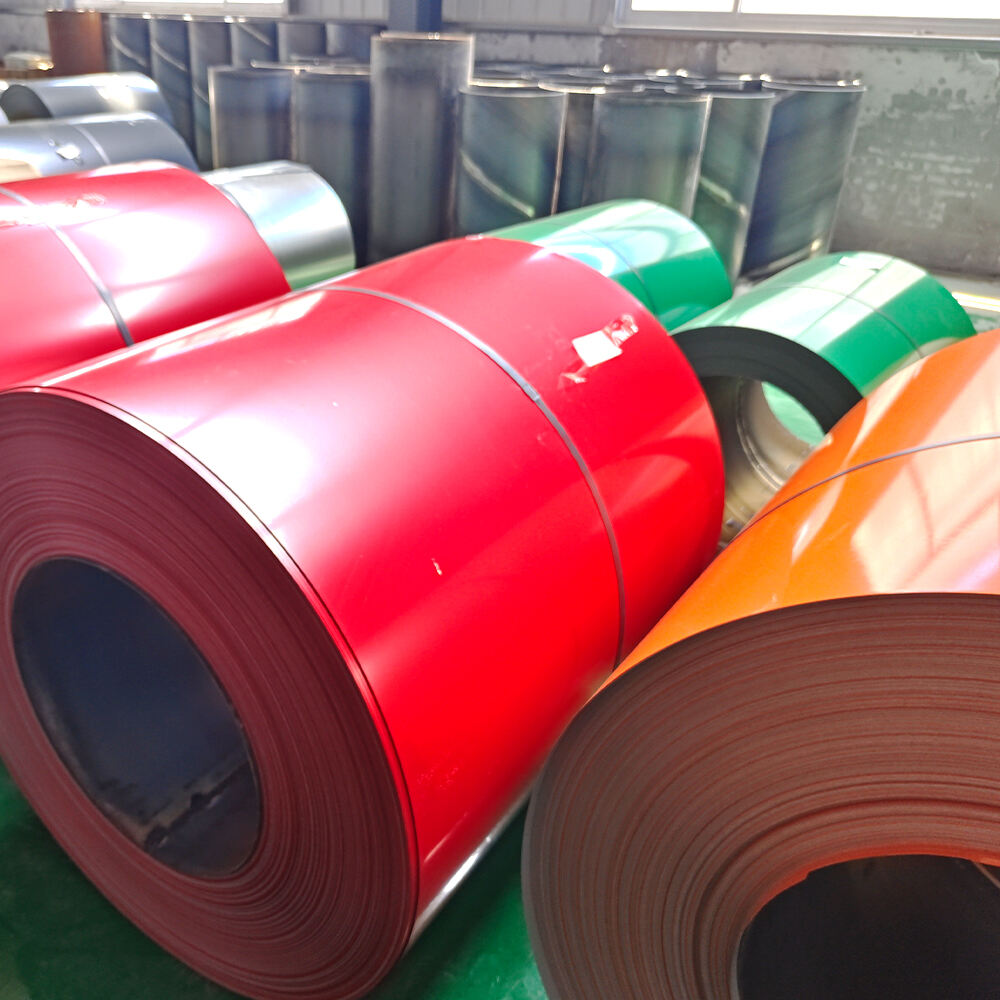

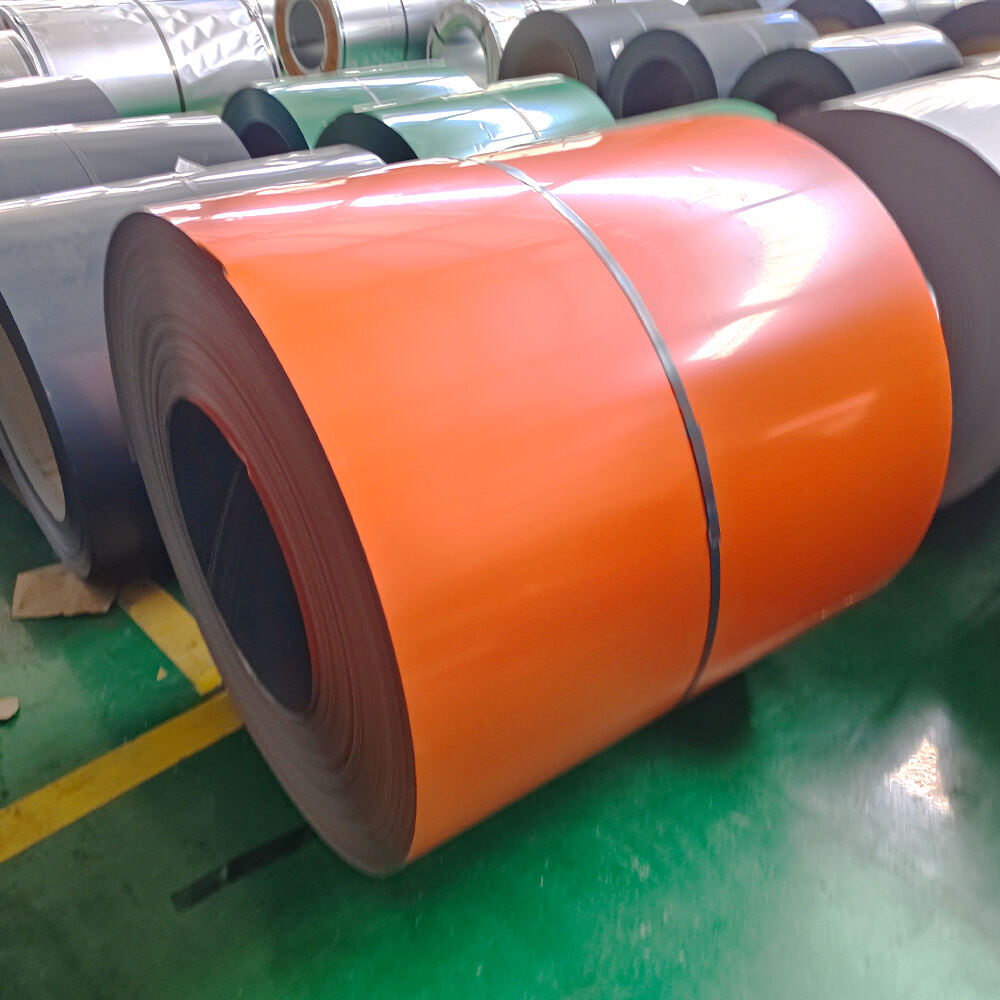

ppgl ppgi

PPGL (Pre-painted Galvalume) dan PPGI (Pre-painted Galvanized Iron) adalah produk baja lapis canggih yang menunjukkan puncak teknologi pengolahan logam modern. Material ini terdiri dari substrat baja yang melalui proses pelapisan canggih, di mana lapisan seng, aluminium, dan cat berperforma tinggi diterapkan untuk menghasilkan permukaan yang tahan lama dan secara estetika menarik. Perbedaan utamanya terletak pada lapisan dasarnya: PPGL menggunakan paduan aluminium-seng sedangkan PPGI menggunakan galvanisasi seng murni. Kedua produk menawarkan ketahanan korosi yang sangat baik, menjadikannya ideal untuk aplikasi eksterior dalam konstruksi dan lingkungan industri. Proses pembuatan melibatkan pelapisan celup panas kontinu, diikuti oleh sistem aplikasi cat yang presisi guna memastikan penutupan yang seragam dan daya rekat unggul. Material ini dirancang untuk tahan terhadap kondisi lingkungan yang keras, termasuk paparan UV, suhu ekstrem, dan paparan bahan kimia. Fleksibilitasnya memungkinkan penggunaan dalam atap, dinding cladding, bangunan industri, fasilitas pertanian, serta berbagai elemen arsitektural. Permukaan yang telah dilapisi cat sebelumnya menghilangkan kebutuhan pengecatan di lokasi, mengurangi waktu pemasangan dan biaya tenaga kerja, sekaligus memastikan kualitas dan tampilan yang konsisten.

×

×