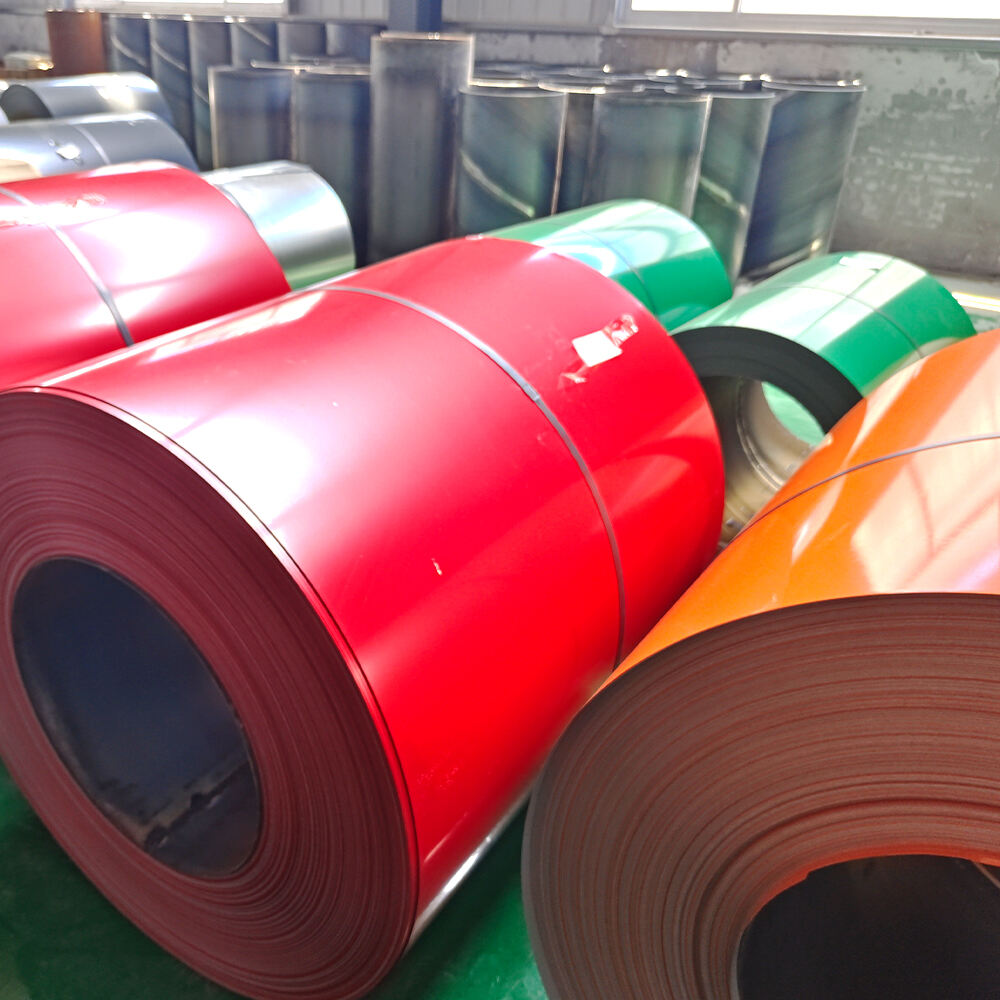

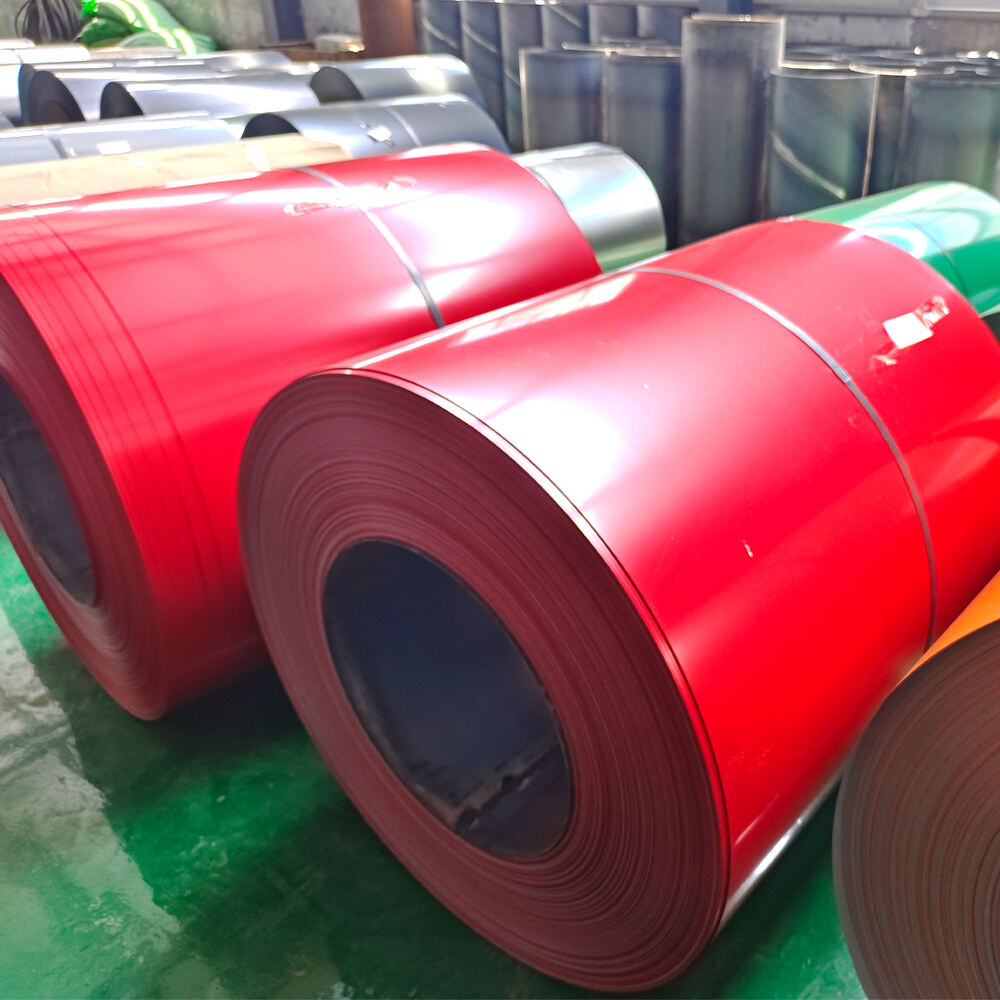

ppgi coil sheet

PPGI coil sheet, also known as Pre-Painted Galvanized Iron coil sheet, represents a significant advancement in construction and industrial materials. This versatile product consists of a steel substrate that undergoes hot-dip galvanization and is then coated with a specialized paint system. The manufacturing process involves multiple layers, including a zinc coating for corrosion resistance, a primer for enhanced adhesion, and a top coat that provides both aesthetic appeal and additional protection. These sheets are produced in continuous coil form, offering excellent flexibility in terms of length and width specifications to meet various project requirements. The material exhibits superior weather resistance, making it ideal for both indoor and outdoor applications. Its durability is enhanced by the combination of galvanization and paint coating, which provides comprehensive protection against rust, UV radiation, and chemical exposure. PPGI coil sheets are engineered to maintain their appearance and structural integrity over extended periods, with typical lifespans exceeding 15 years under normal conditions. The product's versatility is demonstrated through its wide range of applications, from roofing and wall cladding to industrial equipment and appliance manufacturing. The material can be easily formed, cut, and shaped while maintaining its protective properties, making it a preferred choice for both construction professionals and manufacturers.

×

×