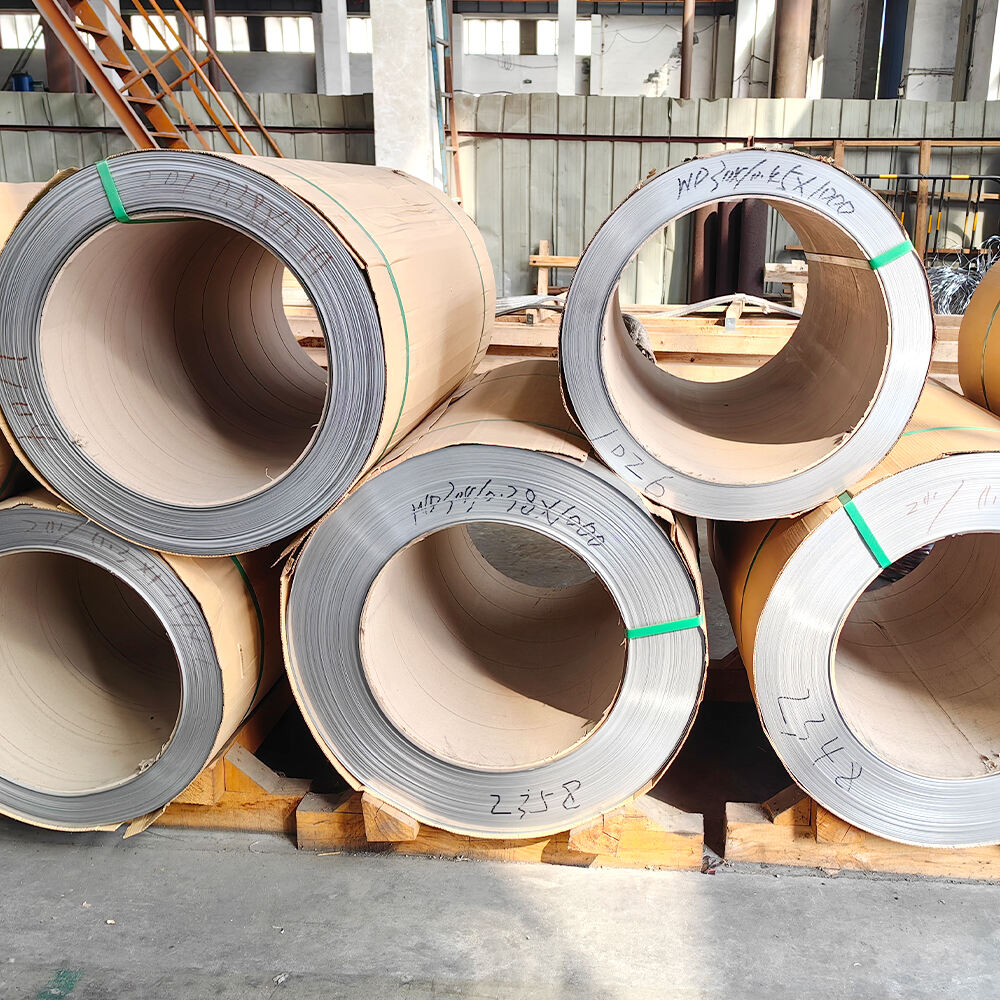

galvanized sheet coil

Galvanized sheet coil represents a crucial industrial product that combines durability with versatile application potential. This engineered material consists of steel sheets treated with a protective zinc coating through a hot-dip galvanization process, creating a robust barrier against corrosion and environmental degradation. The manufacturing process involves passing steel sheets through a bath of molten zinc at temperatures around 860°F (460°C), ensuring complete coverage and optimal adhesion. The resultant coating creates a metallurgical bond with the base steel, providing superior protection compared to other coating methods. These coils are available in various thicknesses, widths, and zinc coating weights, allowing for customization based on specific application requirements. The zinc coating not only provides exceptional corrosion resistance but also offers sacrificial protection, meaning the zinc will corrode preferentially to protect the underlying steel. Modern galvanized sheet coils often incorporate advanced additions such as aluminum and magnesium to enhance coating performance and durability. The material's surface finish can be tailored to different specifications, from regular spangle to minimized spangle or even zero spangle, meeting diverse aesthetic and functional requirements across industries.

×

×