produsen ppgi

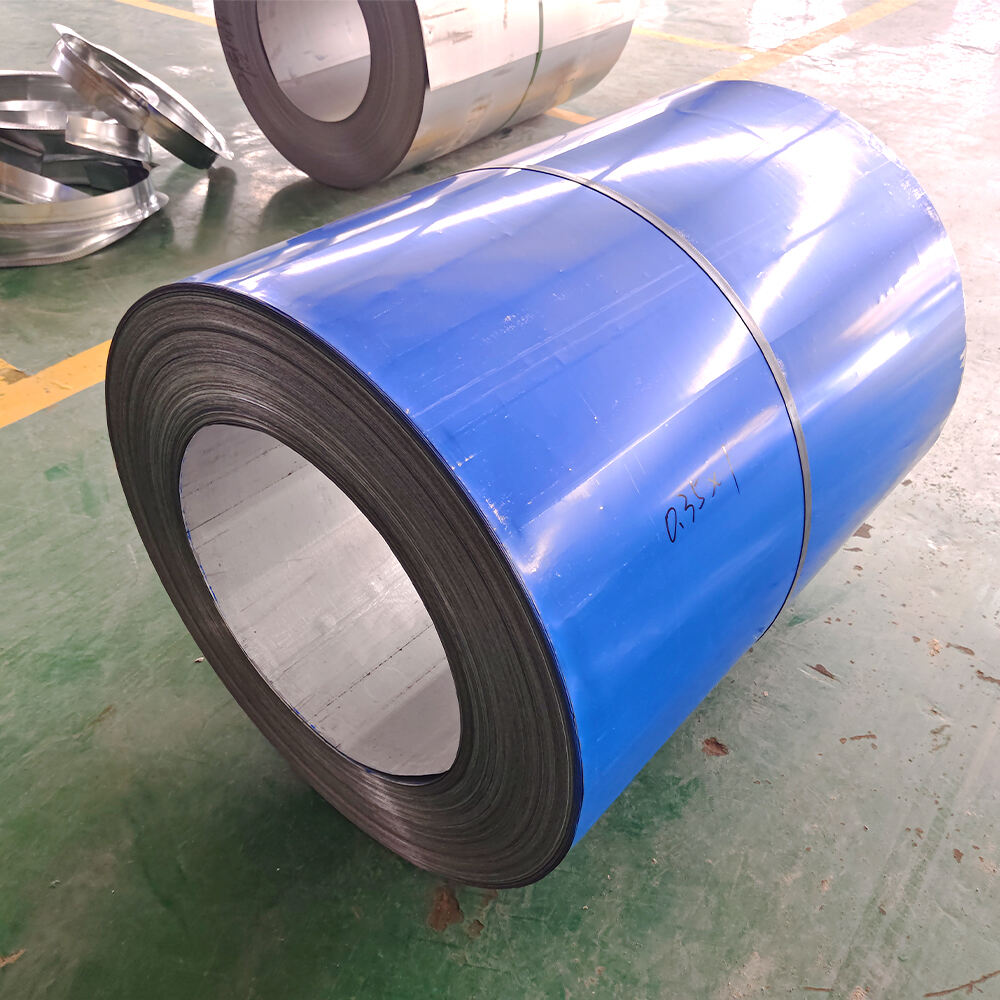

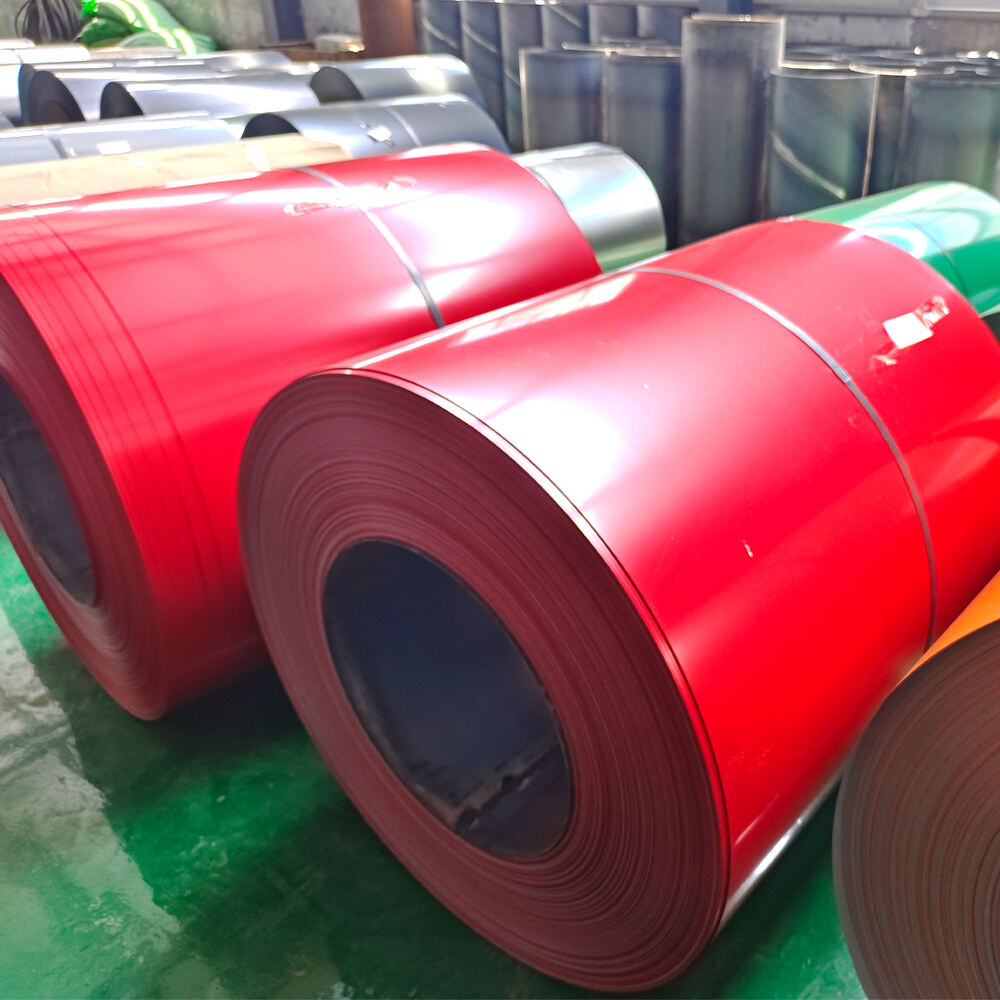

Produsen PPGI, spesialis dalam memproduksi lembaran Besi Galvanis Berlapis Cat (Pre-Painted Galvanized Iron), merupakan segmen penting dalam industri pengolahan logam. Produsen-produsen ini menggunakan teknologi pelapisan canggih dan lini produksi otomatis untuk menciptakan produk baja berkualitas tinggi yang menggabungkan daya tahan dengan daya tarik estetika. Proses manufaktur melibatkan galvanisasi celup panas diikuti oleh sistem pelapisan awal yang canggih, termasuk perlakuan permukaan, aplikasi primer, dan pelapisan akhir. Produsen PPGI modern menerapkan langkah-langkah kontrol kualitas yang ketat sepanjang siklus produksi, guna memastikan konsistensi kualitas produk dan kepatuhan terhadap standar internasional. Fasilitas mereka umumnya dilengkapi peralatan mutakhir untuk persiapan permukaan, aplikasi pelapisan, dan pengujian kualitas, termasuk pengukur ketebalan, penguji adhesi, serta perangkat pengukur warna. Para produsen ini melayani berbagai sektor seperti konstruksi, otomotif, manufaktur peralatan rumah tangga, dan aplikasi industri, menawarkan solusi yang dapat disesuaikan dalam hal ketebalan lapisan, pilihan warna, dan jenis permukaan. Mereka juga menyediakan dukungan teknis dan layanan konsultasi untuk membantu pelanggan memilih spesifikasi yang paling sesuai dengan kebutuhan aplikasi tertentu.

×

×