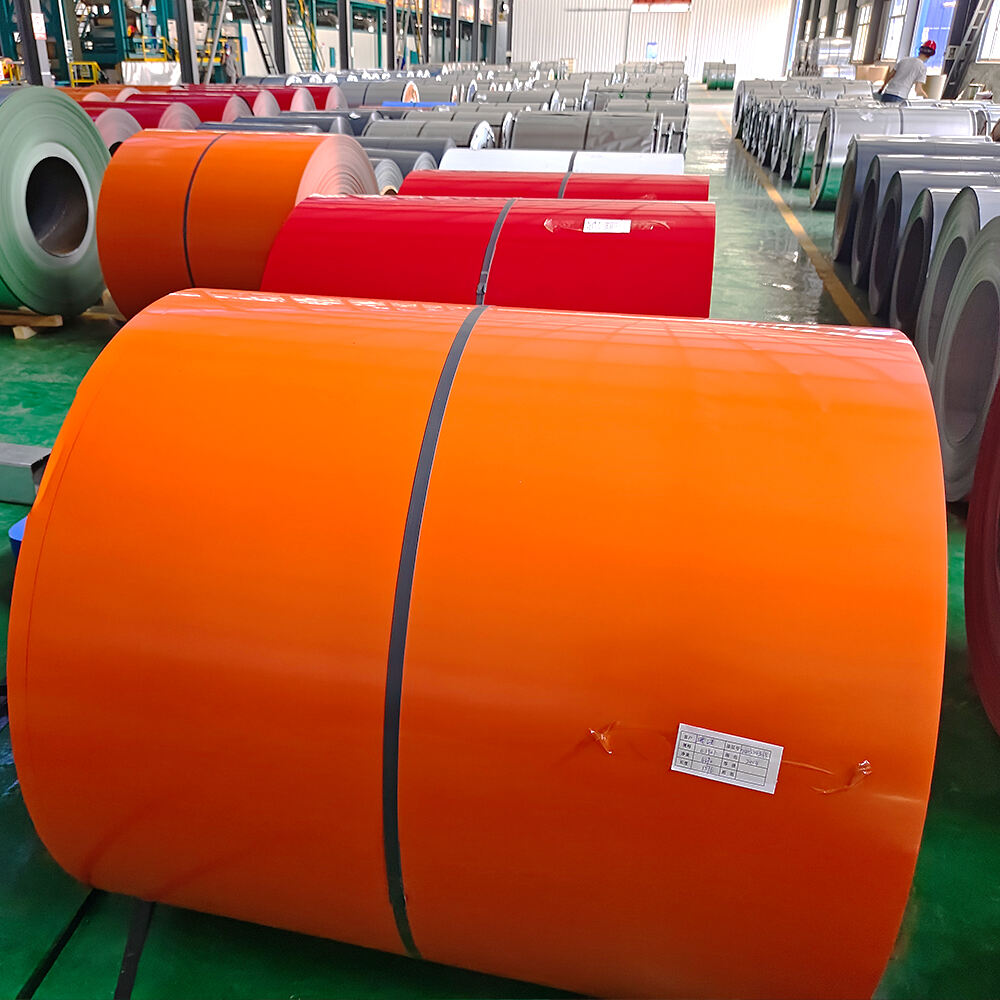

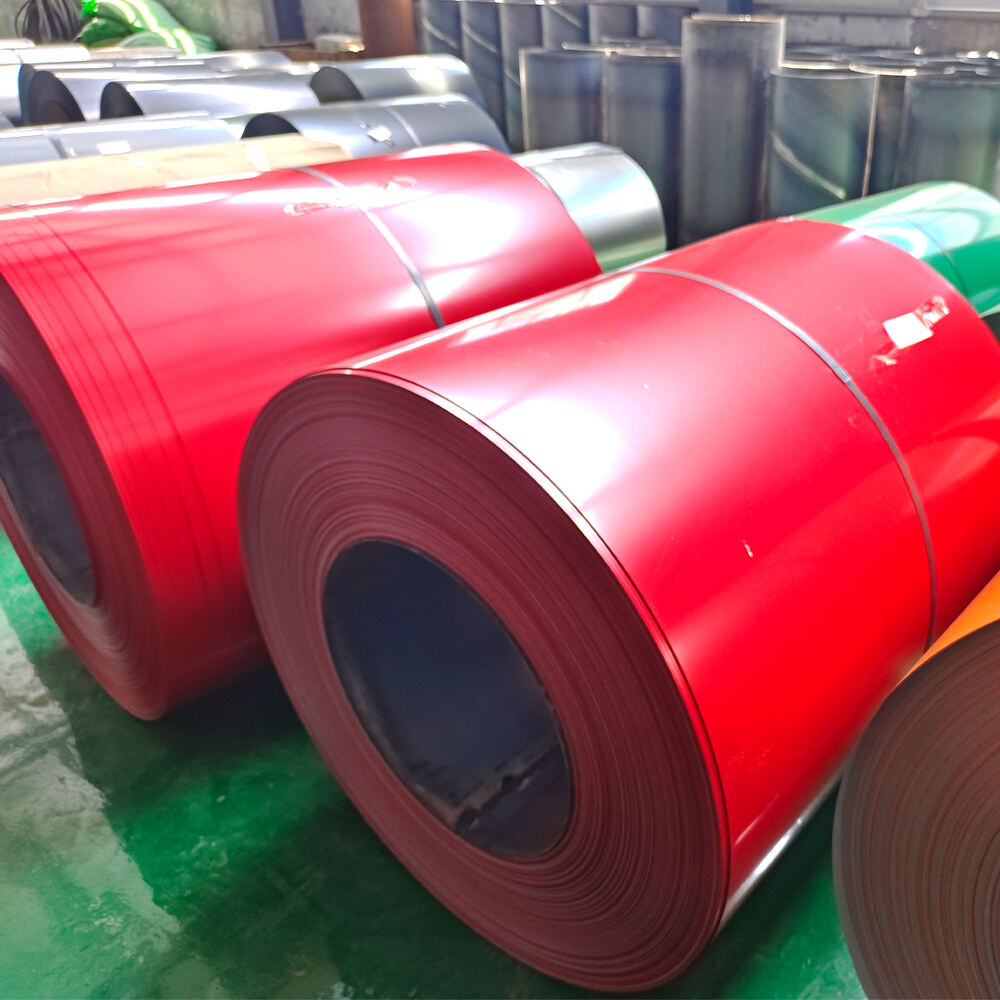

ppgi coated coil

PPGI coated coil, also known as Pre-Painted Galvanized Iron coil, represents a significant advancement in metal coating technology. This innovative product consists of a steel substrate that undergoes hot-dip galvanization and is then treated with a specialized paint coating system. The manufacturing process involves multiple layers, including a zinc coating, primer, and a final color coating, all designed to enhance durability and aesthetic appeal. The coil's structure typically features a zinc coating weight of 60-275g/m2 and coating thickness ranging from 15-25 microns, ensuring optimal protection against corrosion. PPGI coated coils offer exceptional weather resistance, making them ideal for both indoor and outdoor applications. These coils are manufactured under strict quality control measures, incorporating advanced surface treatment technologies that guarantee uniform coating and superior adhesion. The product's versatility is demonstrated through its wide range of applications, from roofing and wall cladding to home appliances and construction materials. The coil's surface can be customized with various colors and finishes, meeting diverse architectural and industrial requirements while maintaining consistent quality and performance standards.

×

×