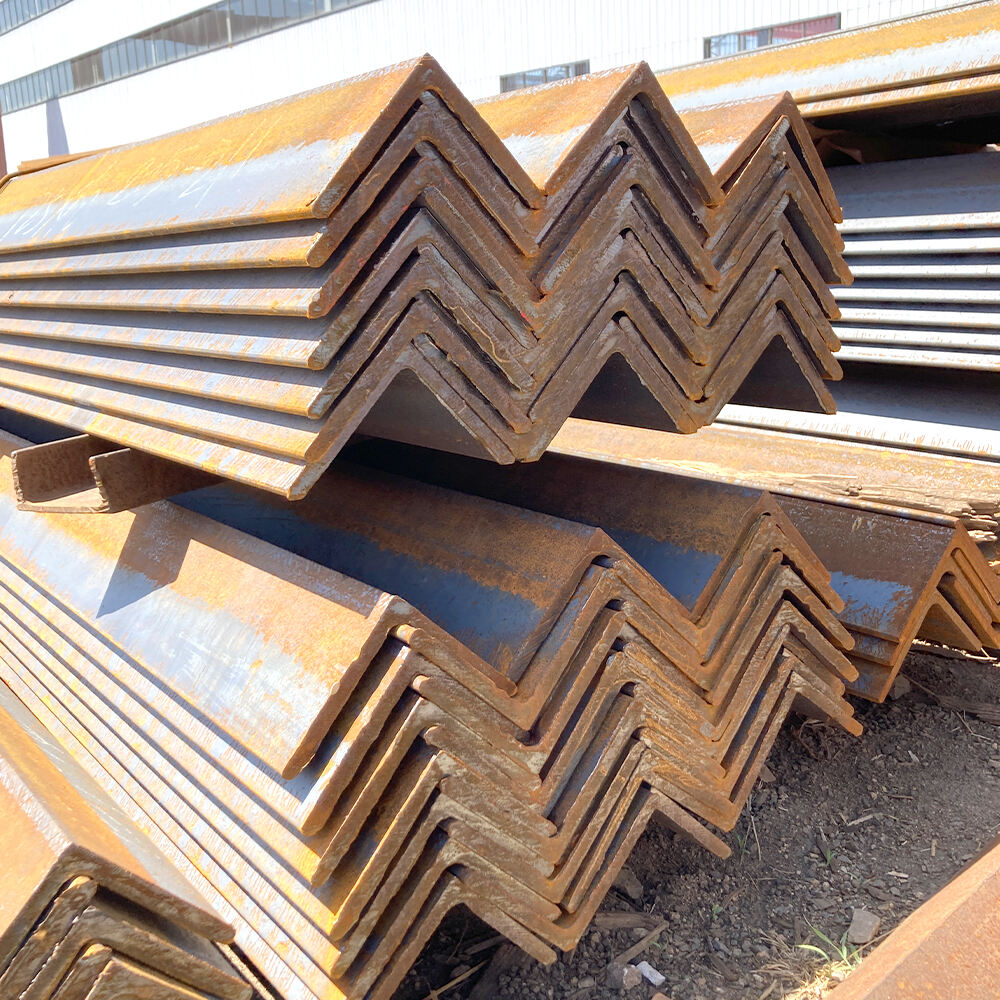

cold rolled angle

Cold rolled angle is a versatile structural steel product manufactured through a sophisticated cold rolling process, where steel is formed at room temperature to achieve precise dimensional accuracy and superior surface finish. This manufacturing method results in angles with sharper corners, tighter tolerances, and enhanced mechanical properties compared to hot rolled alternatives. The process involves passing steel through a series of rollers that progressively shape the material into the desired angle profile, while simultaneously work hardening the metal to increase its strength. Cold rolled angles are characterized by their uniform thickness, exact dimensional specifications, and consistently smooth surface quality. These structural elements are widely utilized in various industries, from construction and manufacturing to furniture making and architectural applications. They serve as crucial components in framework assemblies, support structures, reinforcement elements, and decorative installations. The cold rolling process also ensures better straightness and flatness, making these angles ideal for applications requiring precise fitting and alignment. Additionally, the enhanced surface finish minimizes the need for secondary processing, reducing overall project costs and installation time.

×

×