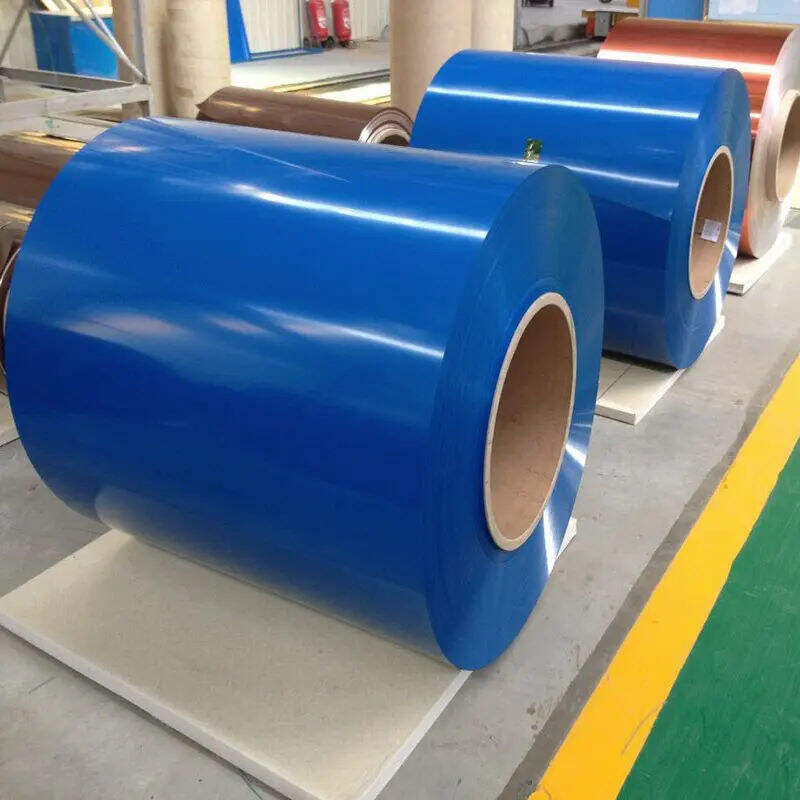

coil galvanized

Coil galvanized steel represents a sophisticated metallurgical process where steel sheets are continuously coated with a protective layer of zinc through hot-dip galvanization. This advanced manufacturing technique involves passing steel strips through a bath of molten zinc at temperatures around 860°F (460°C), creating a metallurgically bonded coating that shields the base metal from corrosion. The process results in a uniform, durable zinc coating that forms multiple layers of zinc-iron alloys, providing superior protection against environmental factors. The continuous nature of coil galvanizing enables manufacturers to produce large quantities of consistently coated material efficiently. The finished product exhibits excellent corrosion resistance, enhanced durability, and superior surface quality. These properties make coil galvanized steel ideal for various applications across construction, automotive, and industrial sectors. The material's versatility allows for post-processing operations such as forming, welding, and painting, while maintaining its protective characteristics. Modern coil galvanizing lines incorporate advanced controls and monitoring systems to ensure coating uniformity and thickness consistency, meeting stringent quality standards and specifications.

×

×