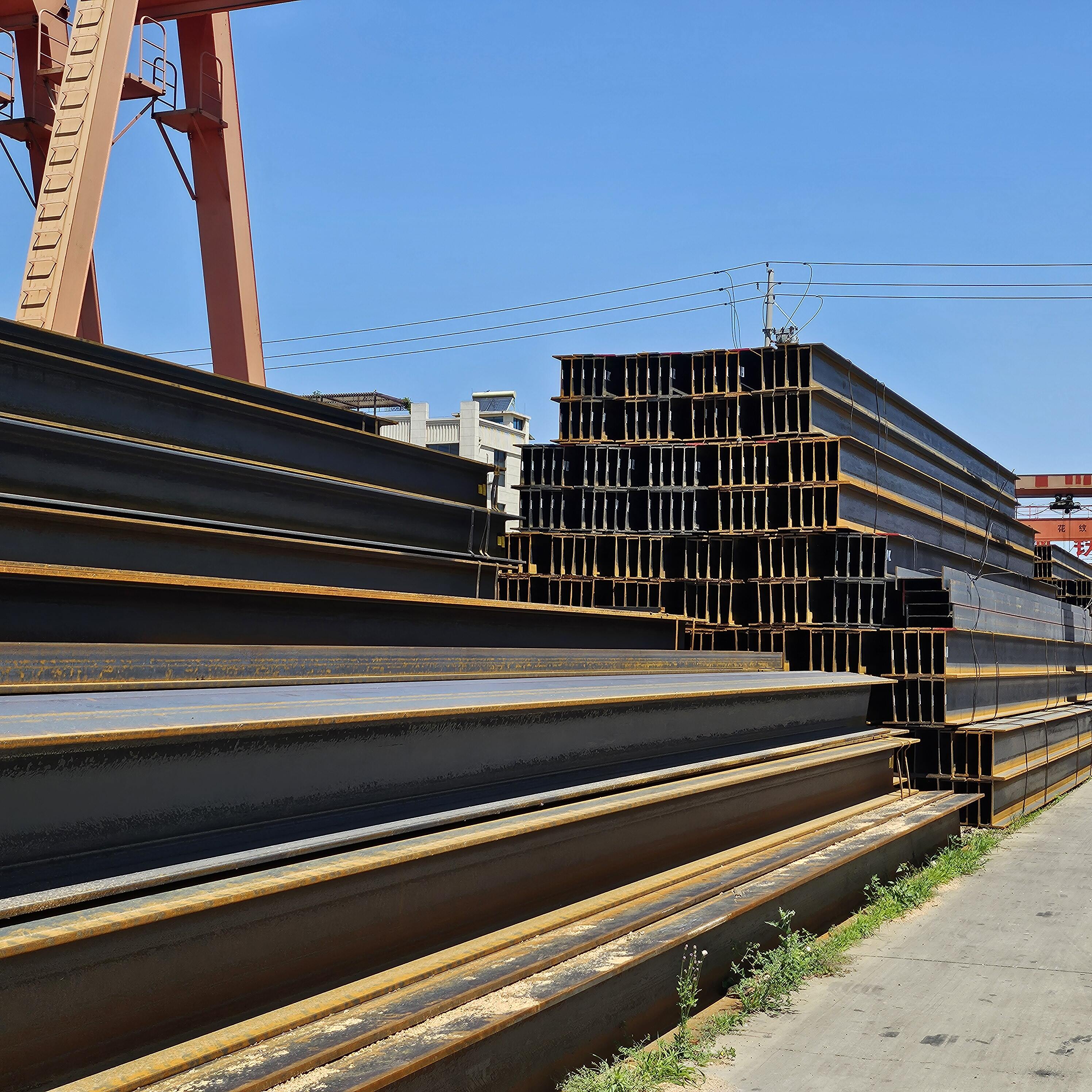

hot rolled steel i beam

Hot rolled steel I beams are fundamental structural elements widely used in modern construction and engineering projects. These load-bearing components are manufactured through a high-temperature rolling process, typically above 1700°F, which shapes the steel into its distinctive I-shaped cross-section. This profile consists of two horizontal elements, called flanges, connected by a vertical component known as the web. The manufacturing process ensures optimal strength-to-weight ratios and superior structural integrity. The hot rolling technique aligns the steel's grain structure, enhancing its mechanical properties and resulting in excellent load-bearing capabilities in both vertical and horizontal applications. These I beams are available in various standard sizes and specifications, making them versatile for different construction requirements. They excel in supporting heavy loads and distributing weight evenly across structures, making them essential in building frameworks, bridges, industrial facilities, and commercial construction projects. The hot rolling process also provides these beams with consistent material properties throughout their cross-section, ensuring reliable performance under various stress conditions. Their standardized dimensions and properties make them ideal for precise engineering calculations and structural designs.

×

×